The use of Iranian nanoceramics in Yazd and Bandar Abbas power plants

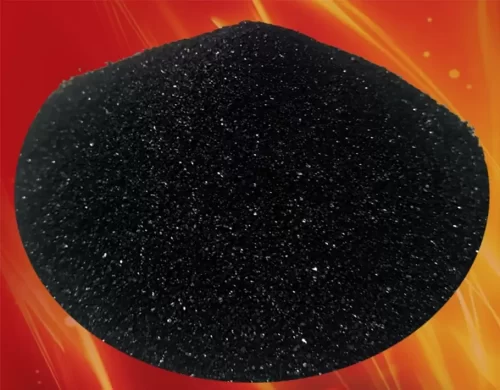

Atlas Seram Desert Company has developed the technology of manufacturing gas turbine combustion chamber ceramics containing nanoparticles, which technology is currently used in Yazd and Bandar Abbas power plants.

Mohammad Hosseinzadeh Yazdi, CEO of Atlas Seram Desert Company, says: “This product is designed and manufactured for power plants that use Siemens design turbines. Mapna company produces this type of turbines under the license of Siemens company, and the ceramics used in it were produced and imported by foreign companies. “We designed and manufactured these ceramics using reverse engineering, in which a combination of nanotechnology and supercooling technology is used.”

Engineer Hosseinzadeh adds: “The technology of making these ceramic enclosures is owned by two companies, Siemens and General Electric, and with the development of this technology inside the country, there is no need to import this product anymore.” “Recently, the Ministry of Industry, Mining and Trade has prevented its import into the country due to the localization of this technology.”

According to Hosseinzadeh, these ceramics must have the ability to withstand high thermal shock, since these ceramics are located near the turbine, any damage and separation of a piece from it can cause serious damage to the turbine and cause very heavy losses. Therefore, nanoparticles are added to ceramic materials to improve the quality of ceramics in the production process, and by performing heat treatment, the thermal shock tolerance of ceramics increases greatly.

CEO of Atlas Seram Kavir says: “Various tests have been conducted by international laboratories on this product and the necessary approvals have been received. This product is included in the vendor list of the Ministry of Energy.

According to Hosseinzadeh engineer, after installing and setting up and working on these ceramics for a long time in Yazd power plant, Bandar Abbas power production management has also started using this product.

Hosseinzadeh considers the acquisition of technical knowledge of this product as a big step for the country in the path of self-sufficiency, a product that also has high export potential.